While heavy-duty hand stitching machines are incredibly effective, they do come with a learning curve. Mastering the intricacies of threading, tension adjustment, and stitch selection is essential for achieving flawless results. Moreover, users must familiarize themselves with the machine’s capabilities and limitations, particularly when transitioning from lighter fabrics to heavier materials.

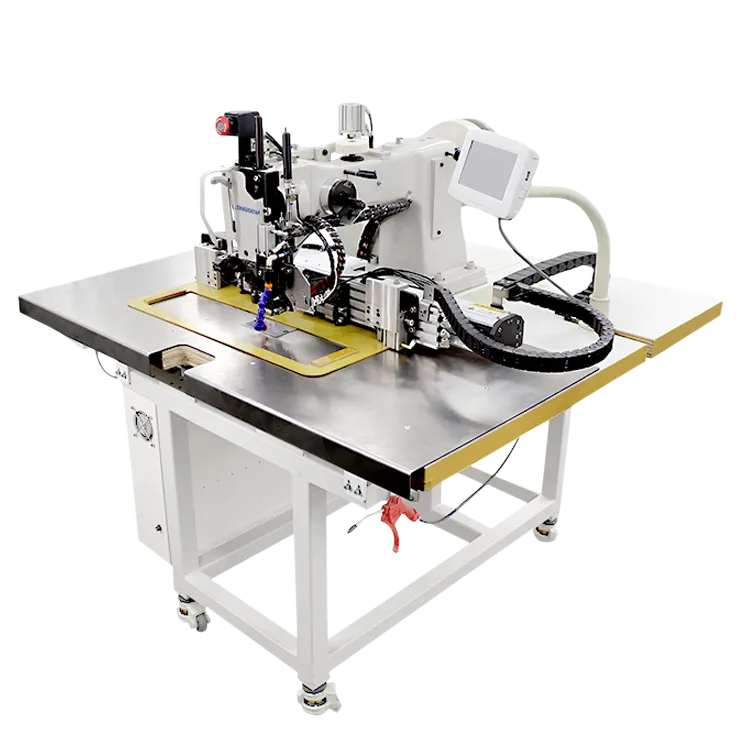

- In recent years, advancements in technology have led to the development of automated woven sack sewing machines that offer increased precision, speed, and efficiency in the production process. These machines are equipped with computerized controls and sensors that monitor and adjust stitching parameters in real-time, ensuring consistent seam quality and reducing the risk of human error.

Rotary hook, working speed is much faster than shuttle hook. Most of garment sewing machine is use rotary hook sewing machine. Also there are very big and strong rotary hook for sewing mid-heavy duty material, like 5-10mm thick. But its working speed is much faster than shuttle hook machine.

2. Walking Foot A walking foot can help prevent layers of leather or vinyl from shifting as you sew, resulting in straight seams and a professional finish. This feature is particularly beneficial for users working on projects that involve multiple layers.

Is it worth getting a heavy-duty sewing machine?

When considering the price of a zigzag sewing machine, it’s essential to think about the long-term investment. While a lower-priced model may initially seem appealing, it might lack the durability and features needed for more advanced sewing tasks. On the other hand, a high-end model might be beyond the budget for casual sewists but could offer more flexibility for those looking to expand their sewing skills.

- The 2% needle lockstitch machine is a crucial tool in the world of sewing and stitching. This machine is designed to create a secure and durable stitch by using two needles simultaneously. It is often used in industries such as garment manufacturing, upholstery, and automotive upholstery.

In the world of textiles and fashion, the tools we use can make a significant difference in our crafting experience and final product quality. One such tool that has gained attention in recent years is the raised bed sewing machine. Unlike traditional sewing machines, raised bed models are designed to provide additional height to the sewing area, making them ideal for handling larger projects, such as quilts or heavy fabrics. This article delves into the features, advantages, and potential applications of raised bed sewing machines.